Surface Roughness and Seeding Process Influence on Boron Doped

Micro/Nanocrystalline Diamond Adhesion on Titanium Substrate by Silvia S Oishi*

in Trends in Textile Engineering & Fashion Technology_

Journal

of Textile Science and Engineering

Abstract

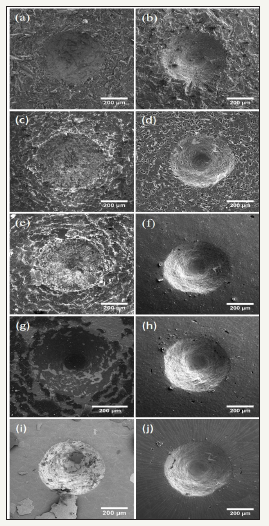

CVD (Chemical Vapor Deposition) diamond deposition on different materials requires surface treatment such as diamond particles seeding on the substrate dispersed in an appropriate solvent by using ultrasonic agitation. On the other hand, seeding process by electrostatic attraction of nanodiamond particle have produced films with higher nucleation density compared to that obtained from ultrasonic treatment. In addition, nucleation and growth of micro/nanocrystalline boron doped diamond films (BDD/NBDD) on titanium (Ti) substrates represent a complex process, mainly due to the poor film adhesion related to the difference in the thermal expansion coefficients between the film and the substrate. Thus, the substrate morphology associated to the seeding process can be determinant for this adhesion. In this context, the adhesion of BDD and NBDD films on Ti substrate was systematically considered in five different Ti surface roughness associated to two different seeding processes: ultrasonic agitation with 0.25μm diamond particle and electrostatic seeding with 4nm diamond particle in potassium chloride.

CVD (Chemical Vapor Deposition) diamond deposition on different materials requires surface treatment such as diamond particles seeding on the substrate dispersed in an appropriate solvent by using ultrasonic agitation. On the other hand, seeding process by electrostatic attraction of nanodiamond particle have produced films with higher nucleation density compared to that obtained from ultrasonic treatment. In addition, nucleation and growth of micro/nanocrystalline boron doped diamond films (BDD/NBDD) on titanium (Ti) substrates represent a complex process, mainly due to the poor film adhesion related to the difference in the thermal expansion coefficients between the film and the substrate. Thus, the substrate morphology associated to the seeding process can be determinant for this adhesion. In this context, the adhesion of BDD and NBDD films on Ti substrate was systematically considered in five different Ti surface roughness associated to two different seeding processes: ultrasonic agitation with 0.25μm diamond particle and electrostatic seeding with 4nm diamond particle in potassium chloride.

Thus, twenty different diamond film sample sets were grown by CVD

technique following the combinations of BDD and NBDD morphologies, Ti

roughnesses, and seeding methodologies. The samples were characterized by

scanning electron microscopy, Raman scattering spectroscopy, and X-ray diffraction (XRD). The

adhesion tests were performed by the Rockweel hardness test according to VDI

3198. The results showed that the BDD and NBDD films grown with electrostatic

seeding with 4nm diamond particle presented the best adhesion regardless of

substrate roughness while only the Ti substrates with higher roughness

presented good adhesion for ultrasonic agitation pre-treatment with 0.25μm

diamond particle. These results indicate that the electrostatic seeding

pre-treatment associated with greater surface roughness have an important role

in improving diamond films adhesion for the two studied morphologies.

Keywords: Micro/nanocrystalline boron doped diamond; HFCVD; Diamond seeding;

Titanium; Adhesion

Please click on the link: https://crimsonpublishers.com/

For more articles in Advances in Journal of Textile Science and

Engineering,

Please click on below link: https://crimsonpublishers.com/tteft/

Follow On Publons:

https://publons.com/publisher/6342/crimson-publishers/

Follow On Linkedin:

https://www.linkedin.com/company/crimsonpublishers/

High impact journals in Crimson Publishers?

https://www.quora.com/What-are-the-high-impact-journals-in-Crimson-Publishers

No comments:

Post a Comment