Texture of Ultrafine-Grained Austenitic Stainless Steels Produced by Martensite Treatment by Mostafa Eskandari in Research & Development in Material Science_journal of materials processing technology

Mini Review

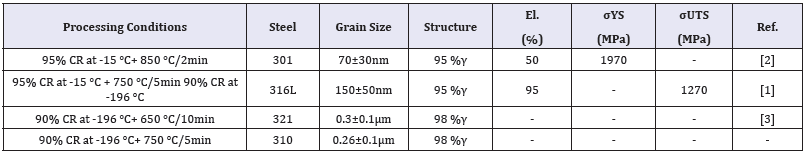

Austenitic stainless steels, for instance 301, 304, 316L, 321 and 310 are widely used in marine structures and petrochemical industry [1]. Such steels are typically characterized by good ductility and excellent overall corrosion resistance. However, they possess relatively low yield strength (200 to 360MPa), which hinders their structural applications. In the past years martensite treatment including 90 percent cold-rolling followed by annealing treatment in the intervals temperatures of 650 to 800 °C have been applied to produce nano/ultrafine grained steels to improve the yield stress of material without sacrificing ductility [1-4]. The details of formation of nano/ultrafine-grained steels have been discussed in our previous work [1-3]. Table 1 depicts the experimental procedure to fabricate ultrafine-grain steels briefly.

Table 1: Effects of different processing parameters on the formation of ultrafine-grained steels.

Figure 1: Orientation distribution function of austenite: (a) 316L steel, (b) 301 steel, (c) 321 steel, (d) 310 steel.

It is evident that preferred crystallographic orientation (texture) of ultrafine-grained steels affect the mechanical behavior of steels. It should be mentioned here that in present study the macrotexture measurements were carried out using a Bruker D8 advance diffractometer with Cr Ka radiation and a 2D Hi-star detector. The initial texture of as-received 301, 316L, 321, and 310 stainless steels was very weak (near ranom). Figure 1 display the orientation distribution function (ODF) sections 0°, and 45° of austenite phase of ultrafine-grained 316L, 301, 321, and 301 stainless steels. As is observed in the Brass ({110}<112>) and a Goss ({110}<100>) textures are appeared in ultrafine-grained steels.

Calculation

Two competitive phenomena influence the texture of ultrafinegrained steels; first, the remaining austenite phase (after coldrolling) is recrystallized during annealing treatment; second, the strain-induced martensite is reverted to austenite during annealing. It is difficult to distinguish the contribution of mentioned effects on texture evolution. However, by annealing at 750 °C the contribution of martensite reversion to austenite is more pronounced on texture evolution compared to conventional recrystallization of remaining austenite [4].

References

- Eskandari M, Najafizadeh A, Kermanpur A (2009) Effect of strain-induced martensite on the formation of nanocrystalline 316L stainlesssteel after cold rolling and annealing. Mater Sci Eng A 519(1-2): 46-50.

- Eskandari M, Kermanpur A, Najafizadeh A (2009) Formation of nanocrystalline structure in 301 stainless steel produced by martensite treatment. Metall Mater Trans A 40(9): 2241-2249.

- Tiamiyu AA, Szpunar JA, Odeshi AG, Oguocha I, Eskandari M (2017) Development of ultra-fine-grained structure in AISI321 austenitic stainless steel. Metall Mater Trans A 48(12): 5990-6012.

- Eskandari M, Mohtadi-Bonab MA, Basu R, Nezakat M, Kermanpur A, et al. (2015) Preferred crystallographic orientation development in nano/ ultrafine-grained 316L stainless steel during martensite to austenite reversion. J Mater Eng Perform 24: 644-653.

No comments:

Post a Comment