Influence of Titanium Oxide on Structure, Corrosion and Soldering Properties of Sn82Bi15Zn3 Alloy by Abu Bakr El-Bediwi* in Research & Development in Material Science_ Materials Science and Technology

Abstract

Our

work study the effect of titanium oxide on structure, soldering properties such

as melting temperature, wetting process and corrosion behavior of Sn82Bi15Zn3

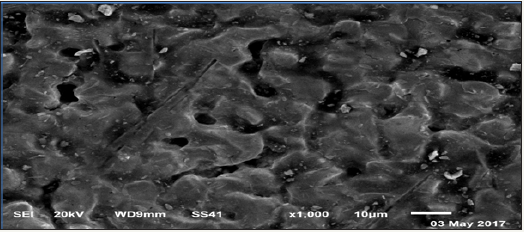

alloy. Microstructure of Sn82Bi15Zn3 alloy

changed after adding different ratio from titanium oxide. Lattice microstrain

of Sn82Bi15Zn3 alloy varied (increased) after

adding titanium oxide. Melting temperature of Sn82Bi15Zn3

alloy varied after adding Ti2O. Sn81.4Bi15Zn3(Ti2O)0.6

alloy has low melting temperature. The contact angle Sn82Bi15Zn3

alloy decreased after adding different ratio from titanium oxide. Corrosion

resistance of Sn82Bi15Zn3 alloy varied

(increased) after adding Ti2O. From our results, soldering

properties (melting temperature and contact angle) and corrosion resistance of

Sn82Bi15Zn3 alloy improved after adding Ti2O.

Introduction

Soldering

is a low temperature

metallurgical joining process. In electronics applications low temperature and

reversibility are especially important because of the materials involved and

the necessity for reworking and making engineering changes. Solder joining is a

wetting process followed by a chemical reaction. Wettability is a function of

the materials to be joined, with Cu, Ni, Au, and Pd, as well as alloys rich in

one or more of these metals, being particularly amenable to soldering. The

chemical reaction following wetting is between the molten solder and the

joining metallurgy to form an intermetallic phase region at the interface.

Microstructure, wettability and physical properties of Sn96-xZn4Bix alloys are

reported by El-Bediwi et al. [1]. The melting temperature of Sn96Zn4 alloy

decreased after adding bismuth. But contact angle of Sn96Zn4 alloy varied after

adding bismuth. Adding silver caused a significant increase in bismuth-tin-zinc

alloy strengthens with a little decreased in melting temperature [2]. El-Bediwi

et al. [2] reported that, there is a significant decrease in melting

temperature of bismuth-tin-zinc

alloy with a very little increase in strengthens after adding indium.

Microstructure, thermal parameters, wettability and electrochemical corrosion

process of Bi30Sn50Sb10A15Zn3Cu2, Bi25Sn61Sb5Zn4Al3Ag2, and

Bi20Sn60Sb7A15Zn3Cd3Cu2, alloys have been studied [3]. Microstructure,

wettability behavior, corrosion parameters, thermal properties of quaternary

bismuth- tin based alloy have been investigated using different experimental

techniques and the results show that, some properties of Bi60Sn40 alloy

improved after adding Sb-Zn or Sb-Ag elements [4]. Tin- zinc eutectic alloy has

been considered as a candidate for lead free solder materials because of its

low melting point, excellent mechanical properties and low cost [5-7]. Mostly

solders are based on Sn-containing binary and ternary alloys. Several elements

have been selected as alloying elements such as Zn, Bi, Cu, Ag, Sb and so on

[8-10]. Specific researchers [11-15] reported that, tin- zinc eutectic solder

alloy is poor wettability, reliability, strength, easy oxidation and microvoid

formation. To avoid these disadvantages or improve the properties of it, they

added minor amount of Bi, Cu, In, Ag, Al, Ga, Sb, Cr, Ni, Ge elements to develop

ternary and even quaternary Pb free alloys. The aim of our work was to study

the effect of titanium dioxide on microstructure, soldering properties and

corrosion of tin bismuthzinc alloy

https://crimsonpublishers.com/rdms/fulltext/RDMS.000630.php

Crimson

Publishers: https://crimsonpublishers.com/

For more articles in Materials Science and Technology,

Please click on below link: https://crimsonpublishers.com/rdms/

No comments:

Post a Comment